DIY MISTAKES

Check out some of the DIY installation mistakes we’ve seen.

Don’t mess around trying to do it yourself.

Installed outdoor outlet with fittings that are not waterproof.

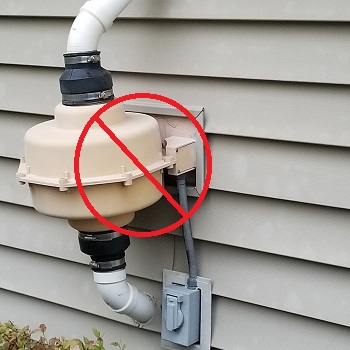

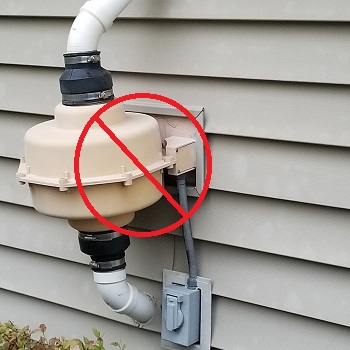

Improperly installed radon mitigation system encountered by Wisconsin Radon Services

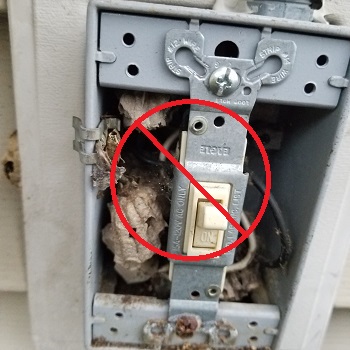

Electrical disconnect is not GFCI protected to protect against shock hazard in garage.

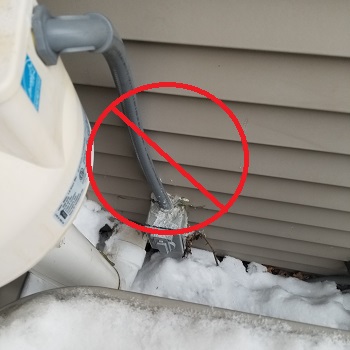

Wrong thickness PVC pipe and fittings used. Too thin of pipe can cause pvc to crack or break off when subject to minimal physical damage or become brittle in Wisconsin weather.

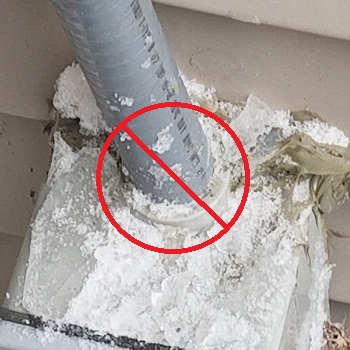

Chiseled through the outside wall causing unnecessary additional damage to the concrete foundation instead of core drilling a hole through the wall.

Inadequate pipe slope caused water/condensate to fill pipe resulting in failure of the radon system and indoor radon levels to become elevated. The water then completely froze in the winter.

Shows the pvc being partially buried in the ground (too thin of pvc) being subject to physical damage (i.e. lawnmowers, foot traffic, etc)

This photo show the pipe which came from the garage originally, traveled approximately 12 feet outside, then reentered the house into the basement. This further illustrates the pipe slope being reversed to get into the house, which resulted in the radon system filling full of water to fail.

This photo show the pipe which came from the garage originally, traveled approximately 12 feet outside, then reentered the house into the basement. This further illustrates the pipe slope being reversed to get into the house, which resulted in the radon system filling full of water to fail.

Used non water proof fittings on an outside system. The flexible conduit he used is not made to fit the connector. This allows water inside the raceway with the electrical wiring. A child could easily pull the wire from the fitting on a circuit that is not GFCI protected. This could cause a dangerous shock.

Used indoor wire through the conduit (raceway) to the fan outdoor.

The wrong size PVC pipe (riser stack coming out of the fan) is too small for proper exhaust. The riser stack should also exhaust at least 1' above the rain gutter. The pipe is not properly secured under the soffit allowing the pipe slope to reverse. The exhaust is removing concentrated cancerous gas from below the basement and exhausting it within 5 feet from a window. This could actually cause higher levels of radon gas within the house.

The fan mounted unbalanced on the siding. The contractor brought the pipe out of the basement at such a steep angle it did not allow for the fan to be level. A different pipe angle and fitting would have given a much more professional looking installation.

A waterproof disconnect that was not properly installed. There was such a gap in the waterproof cover that hornets were able to build a nest inside.

An improperly installed radon system. Code requires the riser stack or exhaust pipe from the radon fan extend to a level at least 1 foot over the roofline (rain gutter or eve). This radon installer (whom is still in business) vented this radon system too close to a window. The cancer causing gas is much more concentrated as it exits the pipe. With the window open the gas can go right back into the house.

Did not use a licensed electrician most likely to save money. The flexible conduit (raceway) is shoved into a box that is not made for flexible conduit. This is not waterproof and can create a dangerous situation being outdoors with possible shock hazard.

Did not use a licensed electrician most likely to save money. The flexible conduit (raceway) is shoved into a box that is not made for flexible conduit. This is not waterproof and can create a dangerous situation being outdoors with possible shock hazard.